Domestic industrial robots have gradually entered the field of higher precision requirements such as automobiles and construction machinery.

Release time:

Dec 12,2018

In 2017, China's industrial robot production increased by 68.1. At the same time, industrial robot manufacturing has continuously broken through the three key core component technologies of reducer, servo control and servo motor, which have been criticized by the industry, and has become a typical representative of China's manufacturing industry accelerating to the middle and high end of the industrial value chain.

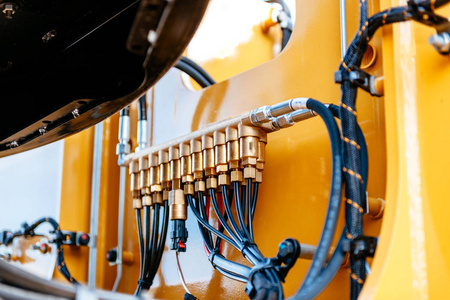

Control system, servo motor and reducer are the three key components of industrial robots, but they have long been dependent on imports. Because of this, the market for six-axis and above high-end industrial robots used in automobile manufacturing and other fields is mainly occupied by Japanese and European and American companies. Domestic six-axis industrial robots account for less than 10% of the new installed capacity of industrial robots in the country.

If you don't conquer the core technology, how can you talk about moving towards the middle and high end of the industry. "In 2017, technological innovation will drive significant transformation and upgrading of the industrial robot industry." Yu Jianing, director of the Institute of Industry and Economics of the Information Center of the Ministry of Industry and Information Technology, said in an interview with a reporter from the Economic Daily that in terms of key components, domestic manufacturers have overcome some problems in key core components such as control systems, servo motors, and reducers. Reaching the international advanced level, key components are gradually localized, which will have a positive effect on reducing the cost of domestic robots and enhancing the market competitiveness and market share of domestic robots. In addition, in terms of software, artificial intelligence technologies such as speech recognition and image recognition have also reached the international advanced level, and significant progress has been made in robot ontology optimization design and performance evaluation, high-speed, high-precision control and other technologies.

Previously, due to the lack of core technology, six-axis and above robots were the difficulty of domestic industrial robots. "The increase in the proportion of six-axis robots represented by multi-joint robots indicates that the adjustment and upgrading of domestic robot product structure is advancing in an orderly manner." Song Xiaogang, executive director and secretary general of the China Robot Industry Alliance, said.